Is the future of mining electric? As mines transition equipment, new risks emerge | 24CA News

Canadian mining firms are beginning to solid apart the diesel-powered vans, loaders, and drills which have long-been the spine of the business for electrical alternate options — a transfer that some business consultants say might make mining safer and fewer polluting.

Mario Santos, mining director for Unifor, Canada’s largest non-public sector commerce union representing 9,900 mining and smelting staff, stated he welcomes the shift. “I think it’s a positive change. It’s better than the processes we were using before,” he informed 24CA News.

Management consulting agency McKinsey & Company estimates that the mining business accounts for four-to-seven per cent of worldwide greenhouse fuel emissions, and business members say electrical mining gear has the potential to decrease these emissions whereas additionally lowering working prices.

More importantly for staff who spend their days working heavy-duty equipment deep beneath the earth’s floor, this swap would clear up the diesel-filled air they breathe day-in and day-out.

But — because the union chief is fast to level out — this variation additionally presents new operational challenges and security dangers. And though electrical gear has been slowly trickling into mines for over a decade, some say there’s nonetheless work to be completed to convey security requirements and coaching on top of things.

“Until we move to a point where we’re able to eliminate those risks — which is a tough thing to do — there’s always going to be a concern,” Santos stated.

‘Electrification is the one resolution’

Today, many essential mining duties will be completed with electrical gear. Electric drills are used to dig into rock, electrical automobiles — like vans and loaders — assist transfer materials round websites, and electrical conveyor belts and pulley techniques do the identical.

North American mines began testing out heavy-duty electrical gear — primarily automobiles hooked up to electrical trolley strains — in the Nineties. But, Canada was one of many first nations to introduce battery-powered electrical automobiles to mining in 2012.

Most within the business have been hesitant to be the earliest adopters of the brand new and largely unproven know-how, stated Dale Rakochy with Sandvik Mining and Rock Solutions, a Swedish engineering firm that produces electrical and diesel-powered mining gear.

“Nobody wants to really be the Guinea pigs with new technology because it does pose some challenges for operations,” he stated.

WATCH | Electric zambonis forestall poisonous fumes:

Ice resurfacers (aka Zambonis) usually run on diesel or propane and might spew doubtlessly unsafe ranges of nitrogen oxides in ice rinks. Now, new know-how helps them go electrical and clear the air.

Now, after practically a decade of use, the know-how is proving its value and hesitancy is dissipating, stated Rakochy. He’s seeing extra mines considering going electrical.

“We will have more mines coming on stream with battery-electric vehicle technology almost monthly now as we go through the years,” he stated, noting that Sandvik’s battery-powered electrical automobiles are presently logging on of their fourth Canadian mine.

Epiroc, one other main electrical mining gear producer out of Sweden, has 16 automobiles working in Canada and expects to have 28 extra on-line by the yr’s finish.

Two latest Sudbury, Ont., mining initiatives have gone the route of full electrification, and different mines in Saskatchewan, British Columbia and Quebec are in varied phases of implementing electrical gear.

Ali Madiseh, an assistant professor on the University of British Columbia’s NBK Mining Institute and Canada Chair in mine power techniques, stated the mining business is searching for methods to cut back emissions, identical to many different industries. For him, electrical gear is critical to realize that objective.

“With the technologies that we have at our disposal right now, electrification is the only solution,” Madiseh stated.

Madiseh notes that gear solely accounts for a portion of the business’s total emissions output, so firms additionally need to decarbonize the ability they generate if they honestly need to scale back their footprint.

Financial advantages, well being advantages

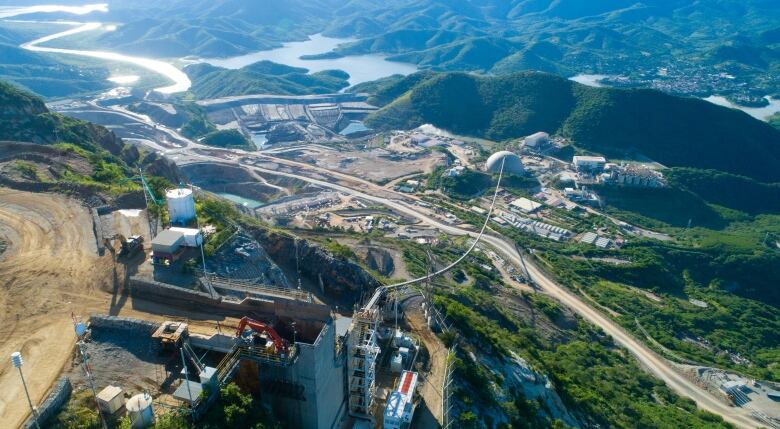

Torex, a Canadian gold mining firm that operates in Mexico, says the way forward for mining is electrical.

The firm makes use of a totally electrical rope-based conveyor system to carry out work that may normally be completed by diesel vans, stated Angie Robson, Torex’s senior vice chairman of human assets, environmental, social and governance, and communications at Torex Gold.

Torex can also be establishing a photo voltaic power plant to assist energy their operations, a transfer Robson stated will scale back their total emissions by 9 per cent per yr.

The firm discovered that utilizing electrical gear additionally makes monetary sense, particularly within the long-term.

“We really were looking at this with the future in mind and the cost benefit did come out beneficial toward the EVs,” stated Robson. “But I think they’ll actually prove even more beneficial as things evolve.”

LISTEN | Are new laws on diesel exhaust in Ontario’s mines robust sufficient?

Morning North7:30Are new laws on diesel exhaust in Ontario’s mines robust sufficient?

The province of Ontario simply introduced new laws on diesel exhaust in mines however are these new laws robust sufficient? We spoke with a researcher from Laurentian University who says they do not go far sufficient to guard staff.

Most mines use advanced air flow techniques — that may value anyplace from $20 million to $400 million to put in, and sometimes require thousands and thousands extra per yr to keep up — to manage diesel emissions ranges underground, stated UBC’s Madiseh.

By distinction, electrical gear does not produce fumes, which implies firms do not need to spend as a lot on costly air flow.

“Diesel particulate matter — DPMs — are a huge concern, and the main reason you have ventilation in a mine is to dilute the diesel emissions,” Madiseh stated.

For Rakochy, the distinction in air high quality between mines that use diesel gear and people who have electrified is stark.

“This will be a bit crude, but you generally will get up and you’ll blow your nose. When you blow your nose, your Kleenex will be full of black soot,” Rakochy stated.

“You know that stuff has definitely gone into your nose and into your lungs. With battery-electric vehicle equipment, there’s absolutely zero of that.”

Particulate matter from diesel engine exhaust is carcinogenic and long-term publicity to those fumes result in an elevated danger of lung most cancers and probably bladder most cancers. A 2018 research discovered that 2.4 per cent of instances of lung most cancers in Canada are attributable to occupational diesel engine exhaust publicity, and underground mine staff have been among the many occupations with the very best danger.

This is among the explanation why Unifor’s Santos welcomes the change.

“From a worker standpoint we’re happy with the move away from diesel, especially when you talk about some issues we’ve seen with diesel particulates,” Santos stated.

Safety issues

But Santos says a part of the problem is that dangers — like electrical fires and car collision hazards — differ between worksites. It will be troublesome to identify these dangers till the gear is working on location, he stated.

Given the confined nature of mines, Santos says his predominant concern is battery fires, a fear shared by Tom Welton, the director of well being and security providers and education schemes at Workplace Safety North.

“It’s not seen very often. If it does happen it can result in catastrophic effects,” Welton stated.

Welton’s danger assessments discovered that fires normally resulted from damages to the battery itself, or by improper dealing with.

WATCH | This firm upcycles previous diesel vans:

U.Ok.-based Lunaz Applied Technologies extends the working lifetime of disused diesel-powered recycling vans by changing them into totally electric-powered automobiles. The firm says it may retain greater than 80 per cent of the unique car’s embedded carbon and likewise lower your expenses.

Sandvik’s Rakochy agrees that fireside is a danger with battery-powered mining gear, however he says that is additionally the case with diesel gear. He says mitigating this danger is a matter of correct schooling and administration.

Workplace Safety North recognized collisions as the commonest danger related with battery-electric automobiles, that are significantly quieter than these with diesel combustion engines. While meaning much less pressure on the listening to of staff, it additionally means there’s an elevated danger of mining automobiles going undetected.

“Battery-electric vehicles can be very quiet and can move very quickly throughout a mining operation and potentially put pedestrians in hazard’s way,” Welton stated.

Last yr, new office requirements for electrical mining automobiles have been launched. Welton says he is glad the requirements launched voltage vary limits for underground mining gear, and supplied measures for the operation and upkeep of electrical gear, however says extra protocols are wanted.

For occasion, he notes there are not any regulatory necessities in place for charging stations — one potential supply of battery fires. Likewise, whereas Welton notes that producers have been supportive in offering coaching to the employees utilizing this gear, he additionally says coaching is a “weakness” within the business.

Cambrian College and Collège Boréal in Sudbury have each began providing industrial battery-electric car upkeep coaching packages throughout the final two years. Welton is working with Ontario’s Mining Legislative Review Committee to establish areas of want and set up new security requirements for the business.

“There’s different challenges and hazards, especially with the voltage that you’re dealing with,” Welton stated. “It has to be dealt with appropriately.”